blog

The evolution of car braking

Today, the use of ABS anti-lock brakes is seen as standard in most cars. To know the evolution of car brakes, we review the history of construction and how to optimize and improve them. Or the continued movement of cars seemed more interesting than braking, and perhaps few people paid attention to the car braking and its vital role.

In 1885, Carl Benz first used wooden brake pads and discs or strap plates to stop his cars. Inventors were used to stop the car, such as Daimler brakes, which included a steel cable wrapped around a metal plate on the inside of the wheel, which forced the vehicle to pull over after a while. It stopped, but one of the biggest disadvantages of such brakes was that when the driver stopped his car at the top of the head, just after the stop, the pressure of this cable was reduced and the car was pulled backwards. Later, a solution for this The problem was solved, and that solution was to use a long spear-like lever that was connected to the traction arms in the back of the car,Stopped.

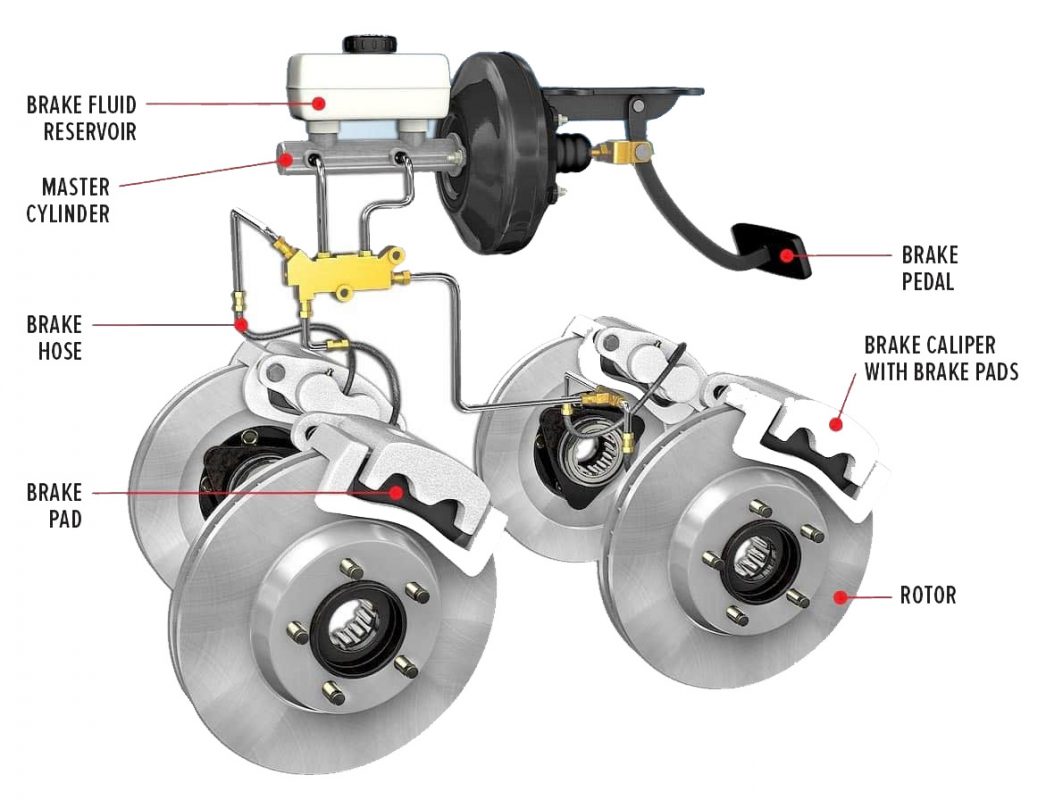

In 1895, the Englishman Frederick Lancaster used a brake-like clutch to stop the car. When the clutch was pulled back, the engine and gearbox were disconnected, and when pulled further back, it was connected to a disc by its wear plate, causing the car to stop. It can be said that braking in all cars was done through the transmission and this was the beginning of disc brakes.

The use of hydraulic transmission systems in the past was only used on bicycles, and in 1897 two people named Bayley and Brigg built and operated the first hydraulic system for four-wheeled vehicles. The force of the springs and their retraction was hydraulic. In 1897 Mr. Herbert Frood focused his work more on the ingredients of what we now call brake pads.

In 1902 he succeeded in opening a company called Frodo, and in 1908 he offered the first sample of his brake pads, which was made of a resistant material called asbestos, to the buyers. Such pads were optimized until 1921, and This year, using casting technology, they got a cheaper price than before. Maybe making brake pads from Asbestos, which is a heat-resistant material, is a fundamental change in making brake pads, because until now, only metal in It was used against metal (discs and pads), and Bugatti continued to use metal against metal until the middle of the twentieth century.

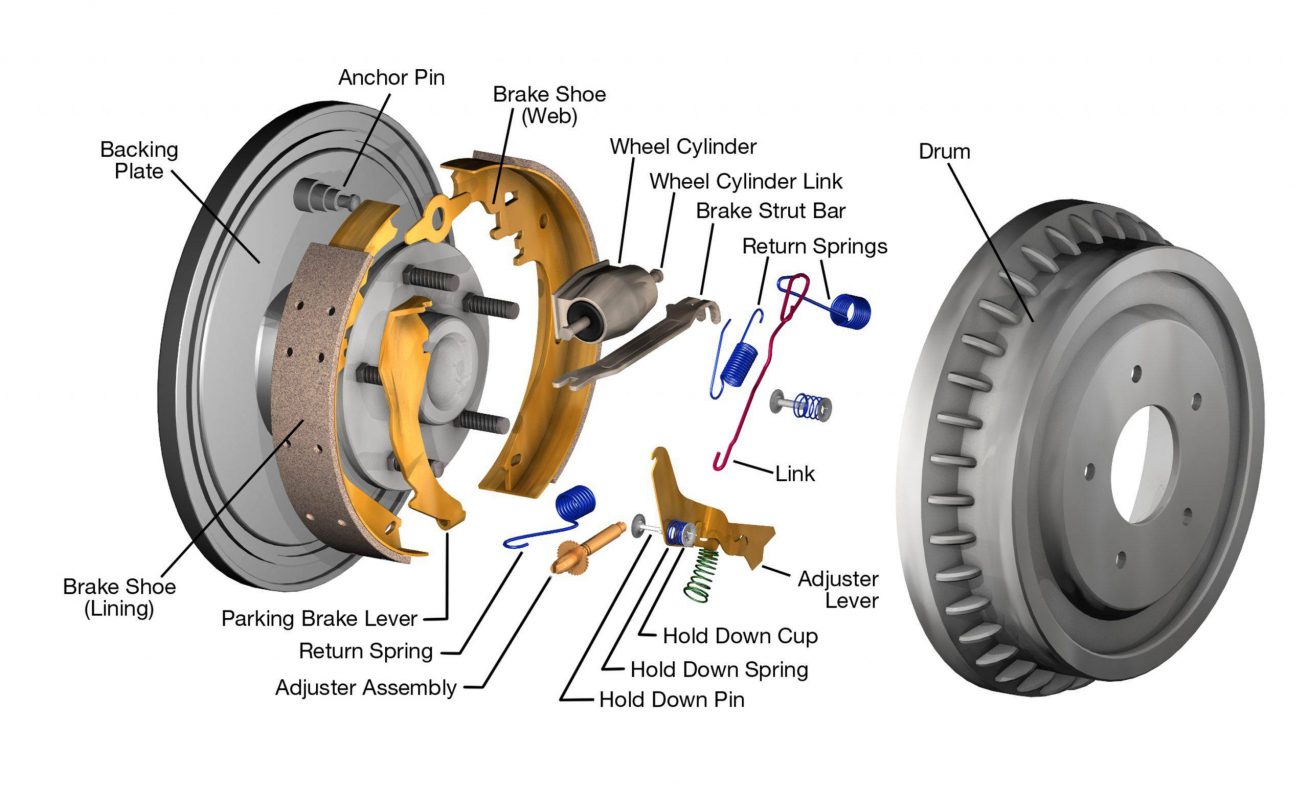

The date of production of disc brakes backs to 1896. In this year, union electicitats gesellscaft company made electromagnetic discs equipped with an erosion plate. In 1901, Mr. Maybach succeeded in making a kind of bowl brake equipped with internal pads. In 1903, these brakes were applied to Mercedes, which also had 40 horsepower. In the same year, Mercedes-Benz also offered the installation of brakes on the front wheels to its customers as additional and custom equipment.

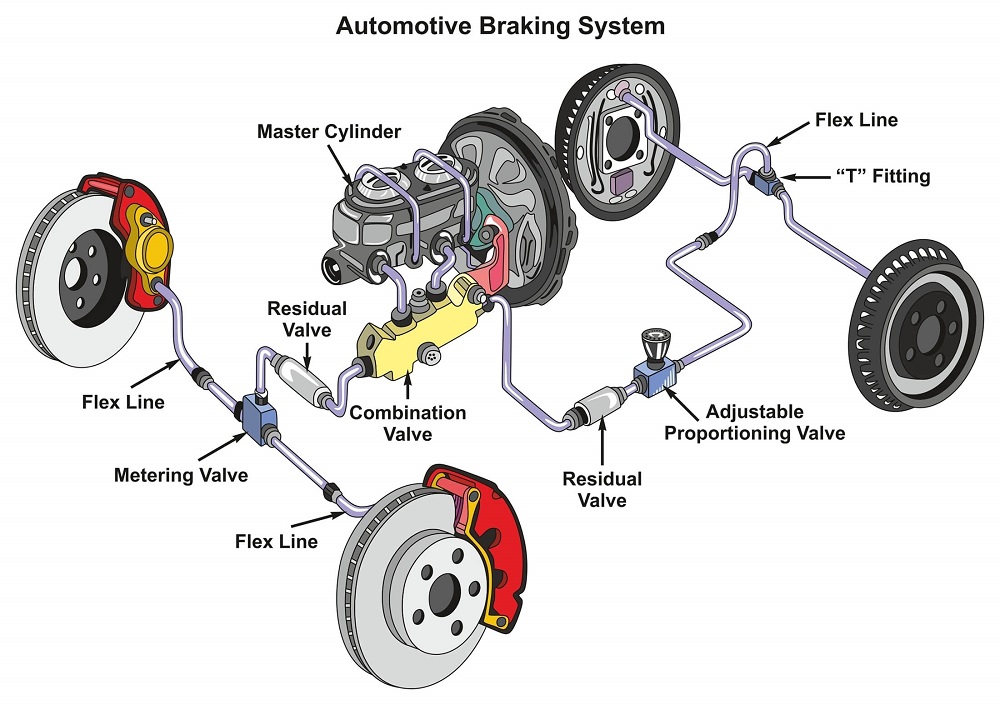

During the 1930s, hydraulics gradually replaced mechanical brakes. Within ten years, efforts to develop hydraulic brakes intensified, especially when independent front brake suspensions were used. In 1935, some British-made models had two main cylinders in a row. In this system, one part of the main cylinder applied the front brakes and the other part applied the rear brakes through a completely separate line.

During the 1930s, hydraulics gradually replaced mechanical brakes. Within ten years, efforts to develop hydraulic brakes intensified, especially when independent front brake suspensions were used. In 1935, some British-made models had two main cylinders in a row. In this system, one part of the main cylinder applied the front brakes and the other part applied the rear brakes through a completely separate line.

In the first half of the 1970s, electronic brake systems were digitized in Europe, a change that resulted in the conversion of analog analysis into microprocessors and integrated circuits (ICs). Which was used in 1979 on a Mercedes car with a Bosch brake system on four wheels with a vacuum or hydraulic booster.

BMW and the Japanese continued this way Bosch ABS was installed on the Cadillac in 1986. Used on Ford in Germany in 1985. In 1991, carmakers proposed the system on a third of cars. Toyota 40%, Nissan 44%, Honda 50%, Mazda 25%, Mitsubishi 27% Chrysler 18%, GM 33%, Ford 13% Until 1992, 15% of cars were equipped with ABS. The reason ABS was not used on small cars was the high price of $ 800 to $ 1,300. GM used effective ABS (ABS-VI) for $ 350 on its 91 cars. The rate of heavy vehicle crashes fell and the number of crashes with Mercedes fell by 6% to 10%.